Patch: Can mount 0201 devices, 0.3 BGA and 0.4 connectors.

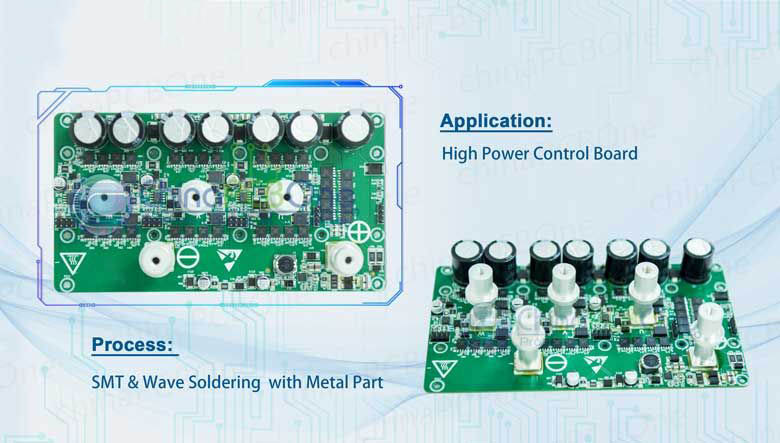

Wave: plug-in wave soldering assembly and burning test

Testing: LCR instrument, AOI, X-RAY to ensure welding quality

ORDER NOWShenzhen Ruibang provides full-inclusive and partially outsourced patch and assembly services. We focus on the placement of rigid boards (PCB) and flexible circuit boards (FPC). Our circuit board patching and assembly processes are quality-driven, ensuring that your finished products are of high quality. All-inclusive placement services, the services we provide include: circuit board manufacturing, component purchasing, software programming, functional testing, online order tracking and finished product assembly. For half-package placement services, you can order the PCB and some components by yourself and provide them to us for placement. You can also reserve the corresponding patch locations for you to mount by yourself.

We are able to assemble BGA, Micro-BGA, QFN and other leadless package components.

Shenzhen Ruibang has a complete global component procurement system, and a professional component team is responsible for your component procurement and component management.

Shenzhen Ruibang provides IC software burning services for electronic devices with advanced functions. All chip software programming is performed before circuit board mounting.

Shenzhen Ruibang's one-stop electronic manufacturing service includes full functional testing (FCT). Functional testing (FCT) is usually performed after circuit board mounting and AOI and visual inspection are completed.

The company focuses on digital and intelligent construction to ensure that every material and every production process meets customer needs. Our intelligent manufacturing system strictly tests all parameters of materials starting from the time they are put into storage, and only allows them to be put into storage after confirmation to prevent human errors. During the production process of each order, the system automatically issues materials according to the customer's BOM, and monitors the usage location of each material during the production process to ensure that the information provided by the customer is consistent.

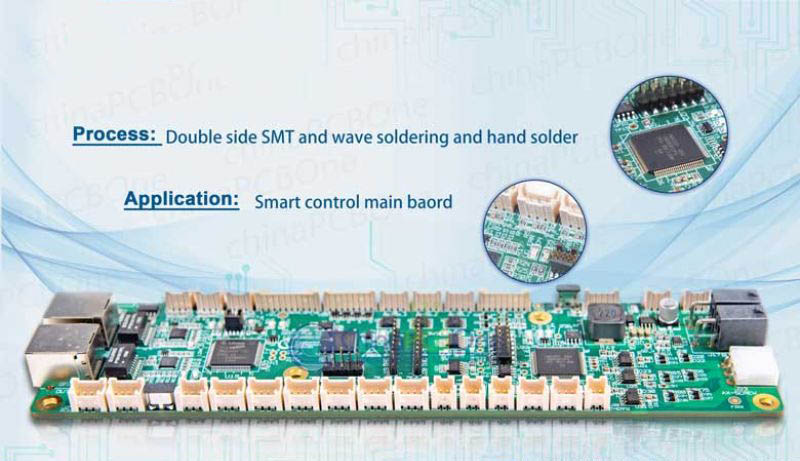

System function motherboard, as a device-type motherboard, usually has a function motherboard, a power control board and an interface circuit board, which together drive the display and control the operation of the device, as well as provide and record monitoring data.

Smart home equipment motherboard: Through wireless communication networks such as Bluetooth or Zigbee, it establishes automatic monitoring, audio-visual, and switch locks of each branch to control home or room appliances and communications.

Automatic control function motherboard is mainly used for various automatic and semi-automatic control electronic motherboards. It calculates and compares through the ARM unit, collects data, calculates, and controls external functional circuits through switches, relays or motors.

PCB+SMT+materials+wave soldering+testing+assembly

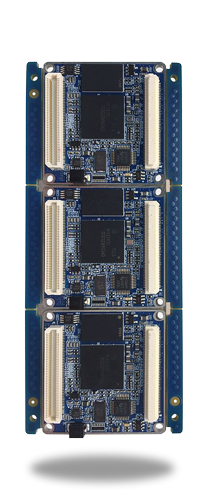

The equipment accuracy can handle 0.2 BGA and 0.2 pitch connectors

Multi-functional universal tray designed with independent patent, can be directly suitable for various irregular PCBs

LCR, AOI, X-RAY, complete testing equipment to ensure welding reliability

SMT usually delivers goods within three days, and plug-in post-welding assembly is postponed by one day accordingly

The products are mainly concentrated in equipment, industrial control, medical, testing instruments, and aerospace motherboards

Self-declared import and export of materials, more than 600 agents and material suppliers, fast response to materials

Domestic adopts next-day delivery and next-day delivery. It can take up to two days to reach the domestic regular delivery location, and it can also be reached in 2-3 days abroad